Many of us find chocolate irresistible. We enjoy it in different forms, flavours and cocoa intensities, but do you know where it comes from and how it is made?

Making chocolate is a more complex process than you might think. From the producer to your grocer, many people are involved in creating this delicious product. It is by paying attention to each step and working with conscientious producers that we are able to obtain the organic and fair trade chocolate bars that make us so proud.

Growing cacao trees

It all starts with the cacao tree, a tree native to Central America and cultivated in several tropical regions of the world. Its Latin name, Theobroma cacao, means “food of the gods” in Greek. Reaching a height of 10 to 15 metres, this tree begins to produce fruits at about 3 to 4 years of age and is at its most productive at about 10 years of age. There are more than than 6 million cacao farmers worldwilde. 90% of these are small-scale farmers with 5 hectares or less.

The fruit of the cacao tree is called a cacao pod. Inside the pod, which looks similar to the size and shape of a football, are 30 to 50 cacao beans. It is these beans that interest us for the production of chocolate!

Harvesting

Although the cacao tree produces fruit all year round, there are usually 2 large harvests a year: one every 6 months. The pods are carefully harvested and then cut in half with a machete to collect the beans. Inside, the cacao beans are covered with a white pulp called mucilage. The outer shell of the pods, which is not eaten, will be left on-site to decompose and nourish the soil.

Fermenting and drying

Once the harvest is over, the beans are fermented. Many of the producer farmers we work with bring their cacao beans to the fermentation centres of their co-op or association for this very important stage. The fermentation of the cacao beans removes mucilage, stops the germination of the seeds and develops the flavours of the cacao. After 6 to 7 days, when fermentation is adequate, the beans are laid out to be dried, often in the sun. This stage, which also lasts about a week, is important for the storage and conservation of the cacao beans. If they still contain too much moisture they may rot, whereas once dry, they can be kept for 4 to 5 years.

Roasting and winnowing

At this stage, the cacao beans leave storage to be processed in a factory. They are first sorted and cleaned, then roasted. This cooking method develops and enhances the flavour of the beans while removing any pathogens that may be present. Finally, the beans are crushed and the outer shell is removed to keep only the small kernel inside, which is called nibs.

Grinding and conching

And now do we have chocolate? Not yet, but almost! The nibs are crushed into a paste. This paste can either be pressed to separate the cacao butter from the cacao solids, which is used to make cocoa powder. Or it can be conched. It is the conching process that interests here us because it leads to the final chocolate bar that can be found in grocery shops. Conching allows the chocolate to be refined by the action of stirring for several hours (24 to 72 hours) at precise temperatures. The result is a smooth paste with lower acidity and more flavour. It is also at this stage that sugar, milk or flavours can be added, depending on the type of chocolate you want to obtain.

And now do we have chocolate? Not yet, but almost! The nibs are crushed into a paste. This paste can either be pressed to separate the cacao butter from the cacao solids, which is used to make cocoa powder. Or it can be conched. It is the conching process that interests here us because it leads to the final chocolate bar that can be found in grocery shops. Conching allows the chocolate to be refined by the action of stirring for several hours (24 to 72 hours) at precise temperatures. The result is a smooth paste with lower acidity and more flavour. It is also at this stage that sugar, milk or flavours can be added, depending on the type of chocolate you want to obtain.

The chocolate bar

Finally, the chocolate paste is slowly tempered to the right temperature. At this stage, it is essential to pay close attention to ensure a uniform crystallization and a smooth texture. Then larger ingredients such as nuts can be added. Finally, the chocolate is poured into moulds to solidify into a beautiful and mouth-watering bar.

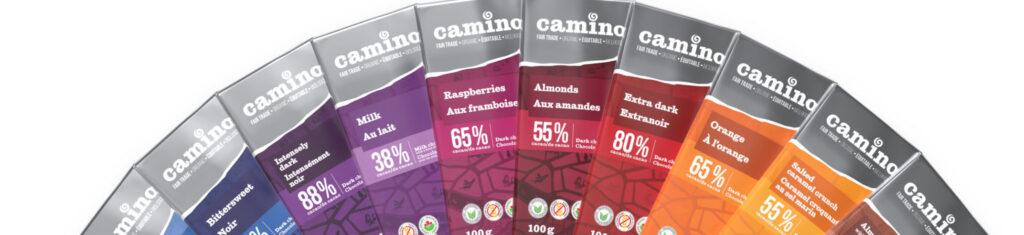

As a fair trade co-operative, it is essential for us to offer quality food products that respect workers and the environment at all stages of production. That’s why our bars are so delicious. Find all our fair trade and organic chocolate bars here, and in your local shop!